Products

Products

Overview:

The American Society of Mechanical Engineers (ASME) first released the Bioprocessing Equipment Standard (BPE) in 1997. Since then, this standard has become a recognized standard specification in the global biotechnology and pharmaceutical industries.

The accessory products produced by QILI comply with the ASME BPE standard, and each component integrates our experience as one of the world's leading manufacturers of stainless steel products. This also applies to the new T-shaped pipe fittings and 88° and 92° elbows that QILI has long produced.

Intelligent manufacturing

Qili selects high-quality imported BPE-specific stainless steel raw materials and adopts the industry's advanced pipe and pipe fitting production and processing, as well as automated inner and outer surface polishing, electrolysis and cleaning equipment. Combining over 20 years of accumulated production process technology experience, and strictly in accordance with the ASME BPE-2022 standard specifications of the United States, we produce and manufacture high-quality SF1 and SF4 full series and pipe fittings products to ensure that they meet the usage requirements of the biopharmaceutical industry.

Product specifications: 1/2"~6",DN10-DN150

Connection methods: Clamp/welding/threaded /DIN/SMS/ISO/IDF/BSP/RJT

Pressure rating: 10 bar /1MPA/145PSI/10 kg

Surface: Internal CNC machining, inner surface Ra0.6um

Material: 304/316L

Temperature: -30℃~200℃

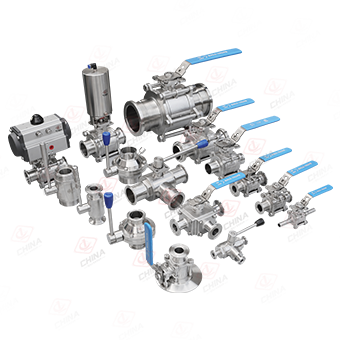

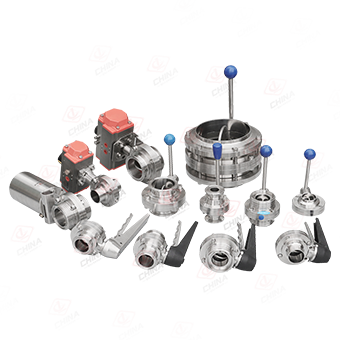

Product specification: 1/2"~8",DN10-DN200

Connection methods: welding/quick installation/threaded/Flange/vacuum

Pressure rating: ≤1.6mpa

Manufacturing standards: 3A/ISO/IDF/DIN/SMS/RJT, etc

Material: SS304/316L

Drive mode: manual/pneumatic/electric, etc

Product specification: 1/2"~4",DN15-DN100

Connection methods: Clamp, welding, thread, 3A,BPM,DIN,SMS,IDF,ISO

Pressure rating: 10bar(145PSI)

Valve body structure: straight-through, three-way, U-shaped three-way, tank bottom valve, multi-channel diaphragm valve

Material: 316L(CF3M)

Diaphragm material: EPDM+PTFE(double-layer), EPDM/Silicom/FPM(Vitong)

Temperature: -20℃~150℃

Certification: 3A-54-02/1580

At an ambient temperature of 70 degrees Fahrenheit, the maximum working pressure rating is 140 pounds per square inch (depending on the valve size).

The clamping end is equipped with a preset EPDM seal.

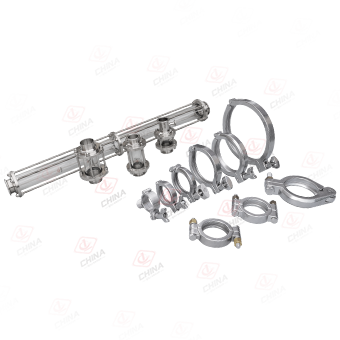

Specification: Connection method: Triangular lamp/welding

Sizes: 1", 1.5", 2", 2.5", 3" or 4"

Material: SS304/316L

Manufacturing standards: ISO/DIN/IDF/SMS/3A, etc

Application scope: food, beverages, pharmaceuticals, dairy products, beer and fine chemicals

Applicable media: gas, liquid, steam

Overview:

Union, also known as union or union, is a commonly used pipe connector that can be easily installed and disassembled. It mainly consists of three parts: nut, cloud head, and flat joint. There are two types of socket joints: equal diameter and reducing diameter.

Specification: DN15- DN150, 1 "- 6"

Manufacturing standards: ISO/DIN/SMS/3A/IDF/RJT, etc

Material: 304/316L

Product features: Attractive appearance, smooth surface, acid and alkali resistant, anti-corrosion, and strong texture performance

Application: The product is widely used in industrial fields such as dairy products, food and beverages, beer, biopharmaceuticals and daily chemical products.

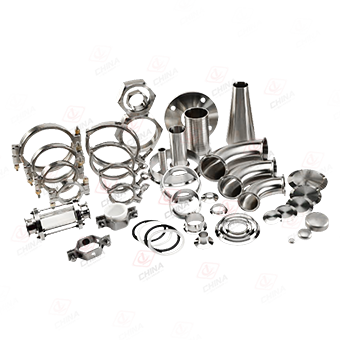

Overview:

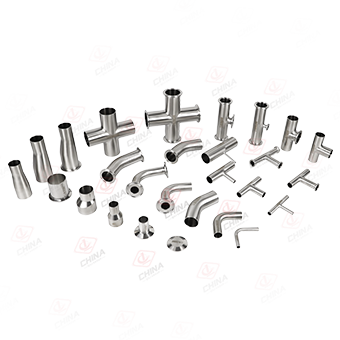

Sanitary grade pipe fittings refer to the sanitary grade pipe fittings used in places with very high hygiene requirements in industries such as pharmaceuticals and food.

Manufacturing standards: 3A/ISO/IDF/DIN/SMS/RJT, etc

Material: 304/316L

Application: It is applicable to industrial fields such as dairy products, food, beer, beverages, pharmaceuticals, and cosmetics

Applicable media: water, oil, gas and certain corrosive liquids

Product features: Attractive appearance, smooth surface, acid and alkali resistant, anti-corrosion, and strong texture performance

Application:

In order to observe the operation status of equipment and the working condition of the system more intuitively and conveniently, sight glasses are widely used in fields such as brewing, beverages, pharmaceuticals and dairy products.

Design standard:

QILI can provide straight-through sight glasses, illuminated sight glasses and four-way sight glasses. The straight-through sight glass can be installed horizontally or vertically, allowing for 360° observation through glass protection. It is particularly suitable for online observation of pipelines. The illuminated sight glass is a union type sight glass, featuring the ability to be observed under light and the convenience of disassembly and replacement. It is suitable for observing tank equipment.

Working temperature :-20~+135°C(when the seal is EPDM)

Material: Steel parts :304 or 316L

Sight glass material: Silicon boride glass (straight sight glass), silicon boride glass, tempered glass (union sight glass)

Application: Suitable for use in pharmaceuticals, biomedicine, cosmetics, and food processing

Material: SUS304, SUS316L

Pipeline flow control: DN25-100 and 1-4

Connection methods: welding type, quick-installation type, threaded type

Manufacturing standards: 3A/ISO/DIN/FDA, etc

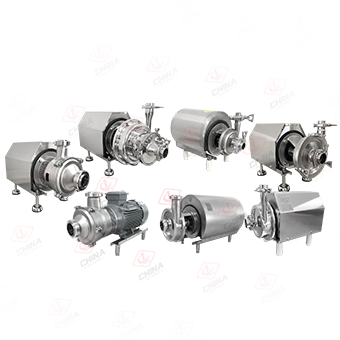

Overview:

Sanitary pumps are classified based on their usage scenarios, specifically involving the transportation of all products that come into contact with the human body, such as pharmaceuticals, dairy products, beverages, food, cosmetics, food additives, fine chemicals, etc. There are four basic types of sanitary pumps: centrifugal, volumetric, jet, and air transport. Centrifugal pumps apply centrifugal force to generate speed, using rotating impellers to increase speed and push fluid through the outlet valve.

Features:

The excellence of Qili pump stems from many factors. The high performance and energy efficiency of our pump stem from its internal geometric characteristics, ensuring excellent fluid properties and a simple CIP combined with the pump's sturdy structure, guaranteeing trouble free operation and low maintenance requirements. On the other hand, every design detail of the Qi Li pump avoids drawbacks. From precise balance design and placement of thrusters to external springs for pump shaft seals (without using internal springs). Most of Qili's sanitary centrifugal pumps use the same mechanical shaft seal, which simplifies the installation and inventory of components. The product series of Qili Pump all have the same modular characteristics, simplifying maintenance, modification, and sealing conversion.

The height (H), collar (t) and cover (t1) can be customized according to your requirements.

Features:

◆ Sealing material: Silicone, ethylene propylene diene monomer (EPDM), nitrile, fluororubber, in compliance with FDA177.2600;

◆ Material: 304(1.4301),316L(1.4404)

◆ Inner surface treatment: 0.8μm-0.4 μm

◆ Outer surface treatment: Mirror polishing, matte finish, sandblasting treatment.

Purpose:

It can be applied to industrial fields such as dairy products, beer, food, beverages, pharmaceuticals, and bioengineering.

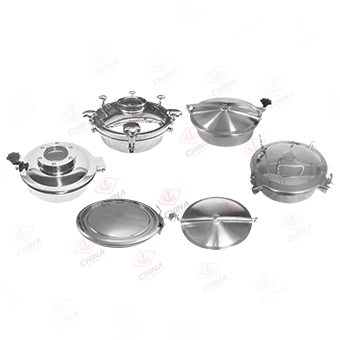

Type:

Atmospheric pressure type, pressure type with sight glass, handwheel type, rectangular type, elliptical type, elliptical type with mirror, handhole type, square type, etc.

Our professional sales engineers are always at your disposal to provide you with advice and assistance to provide you with suitable solutions.